- A two-part anti-corrosion primer is based on polyamide hardened epoxy resin and containing iron oxide pigment.

- These coatings are used as a primer for steel surfaces due to its good corrosion resistance in humid environments and marine areas. iron oxide shows good resistance under partial and complete immersion in water because of the anti-corrosion pigment.

- This product has high chemical resistance as well as high adhesion to metal surfaces and compatibility with various systems for subsequent layers such as epoxy and polyurethane in a variety of industries and is often repainted by surface coating for decorative or protective purposes. This primer also has the ability to harden completely, release all solvents and prevent from pigment migration to the water phase.

- This liner is used to protect the inner and outer surfaces of water tanks, pipes, and water transfer connections.

- Protecting metal structures that are exposed to corrosive conditions is another feature of iron oxide liner.

- This group of primers and paints have properties such as abrasion resistance, resistance to chemicals, solvents, high adhesion strength, high hardness and good impactability.

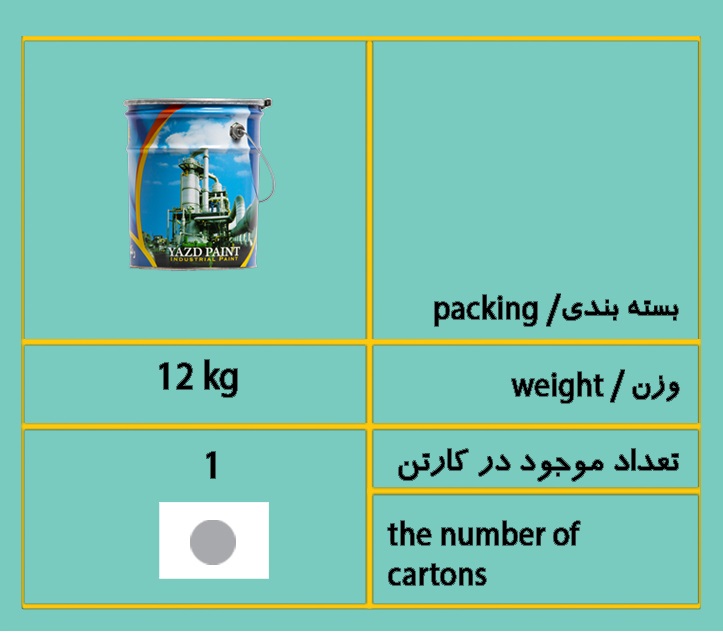

Ochre Epoxy polyamide primer

• The surface must be free of any contamination, grease or moisture. • • If the overlay expires, it is necessary to rough the surface and then wash it with a suitable thinner to increase the interlayer adhesion. • • It is recommended to apply the paint at an ambient temperature above 10 ،, a surface temperature of 3 degrees above the dew point and a humidity of less than 80%. • •This paint can be applied using the methods of brush, ordinary spray, airless spray. • For better coverage of corners, edges, out of reach places and welding lines, the use of brushes or rollers in addition to spray, is highly recommended. To achieve the desired thickness at these points, it may be necessary to apply several times with a brush or roller. • The amount of thinner varies from 30 to 35% depending on the method of application, but use the least possible amount. Increasing the thinner requirement may cause of leaching and long the drying time

• Store the product in a main package away from direct sunlight and in a cool and dry place. • This coating is based on solvent and has high flammability. Care should be taken to avoid inhaling dust from separate sprays. • Avoid contact of the paint film with wet skin and eyes separately. • Safety principles regarding incendiary materials must be observed in transportation and storage. Proper ventilation should be used when applied indoors to prevent explosions (this also facilitates better drying of the paint). When applying, be sure to wear special work clothes (to cover all parts of the body), safety gloves, proper respirators and goggles.